The semiconductor industry is always looking for ways to make well-established technologies last longer. The 28nm process technology, which is an established way of producing semiconductors, is important in this field. Even though there are newer, smaller ways of making semiconductors, 28nm is still popular. It is chosen often for many different uses because it balances cost, performance, and power usage. This way of making semiconductors is the foundation for many devices.

It keeps getting better through improvements in the way it is made and designed. Companies are working on making 28nm better by adding new things to meet the different needs of modern electronics. This helps 28nm chips work well in areas like mobile application processors and fast networking. Manufacturers have also made it easier to design things that use 28nm, making it faster to get new products to market. These changes make sure that 28nm continues to be a good choice for making semiconductors for a long time.

This guide will break down what 28nm technology is, how it works, and why it remains so relevant.

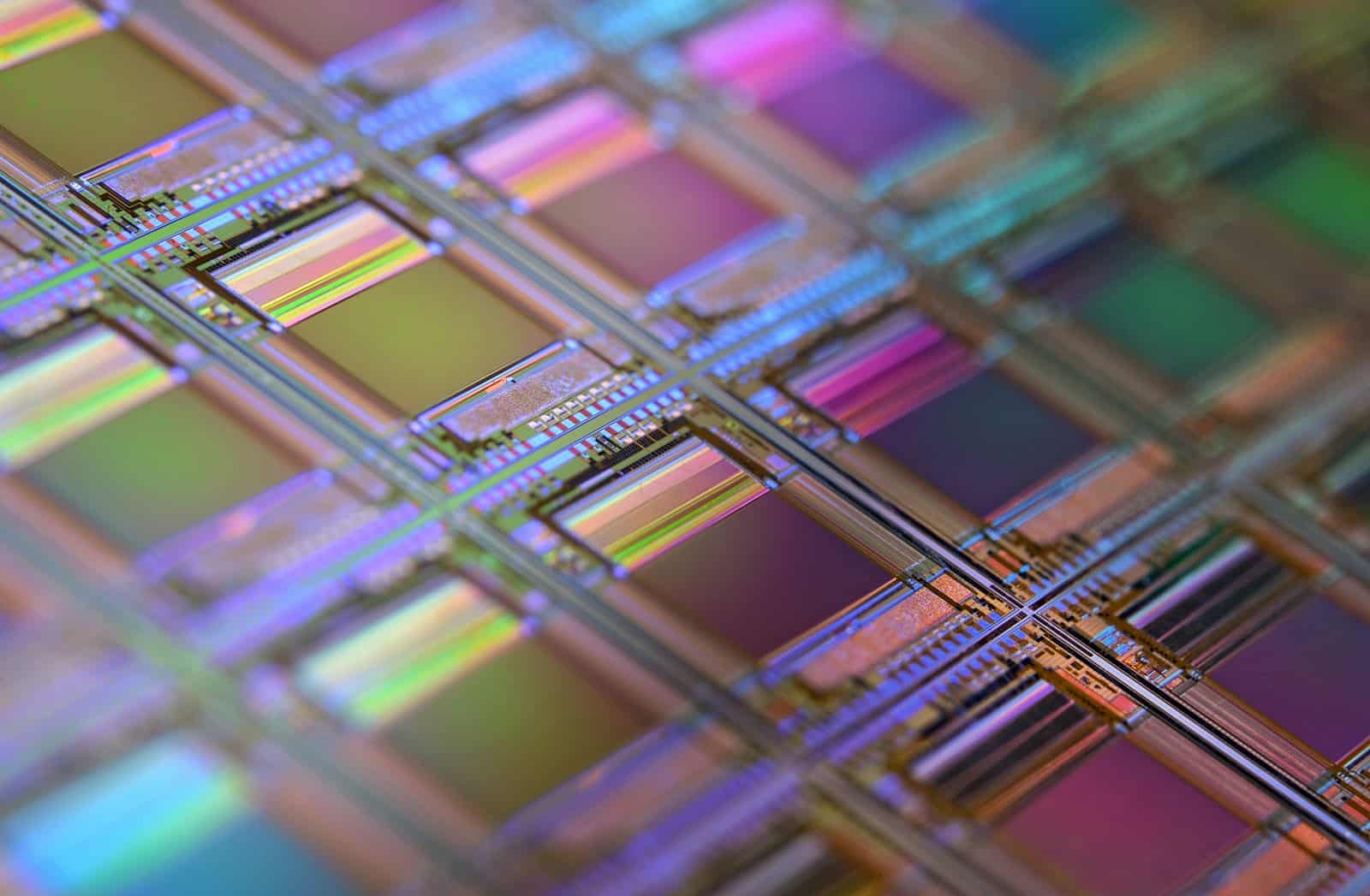

1. What Does “28nm” Mean?

In the semiconductor world, terms like 28nm, 16nm, or 7nm describe the technology nodes used to manufacture chips. Among these, 28nm technology is one of the most important milestones. It represents a sweet spot between performance, cost, and power efficiency—so much so that it’s still widely used today, more than a decade after its debut.

- “28nm” refers to the process node used in semiconductor manufacturing.

- Historically, the number indicated the smallest half-pitch (distance between features) on a chip.

- At 28nm, transistors are about 28 nanometers wide—roughly 1000 times smaller than a human red blood cell.

- In practice, modern naming conventions are more marketing-driven than literal, but 28nm still represents a real generational leap from 40nm and 32nm processes (source: Wikipedia).

2. When Did 28nm Technology Arrive?

- Introduced around 2010–2011 by leading foundries like TSMC, GlobalFoundries, and Samsung.

- TSMC was the first to offer 28nm mass production in 2011 (source: TSMC).

- It marked the transition from 40nm planar CMOS to a smaller, faster, and more power-efficient node.

3. Key Features of 28nm

- Planar CMOS – Unlike later nodes that use FinFETs (3D transistors), 28nm still uses traditional planar transistors.

- Lower power consumption – Much better efficiency compared to 40nm.

- Higher performance – Faster switching speeds and higher transistor density.

- Multiple variants – Foundries offered different “flavors” of 28nm, such as:

- 28HP (High Performance)

- 28LP (Low Power)

- 28HPM (High Performance Mobile)

- 28HPC (High Performance Compact)

This flexibility allowed 28nm to serve a wide range of applications.

4. Why 28nm Was a Game-Changer

- Cost-effective scaling – Provided significant improvements without the steep costs of newer nodes.

- Broad adoption – Used in CPUs, GPUs, FPGAs, baseband processors, and consumer electronics.

- Longevity – Unlike some nodes that quickly became obsolete, 28nm has remained in production for over a decade.

5. Applications of 28nm Technology

Even today, 28nm is widely used in:

- Smartphones (early generations) – Many early 4G LTE chips were built on 28nm.

- Graphics processors – AMD and NVIDIA both used 28nm for entire GPU families.

- FPGAs and ASICs – Popular for custom logic and reconfigurable chips.

- Automotive electronics – Reliable and cost-effective for cars, where bleeding-edge nodes aren’t always necessary.

- IoT and embedded systems – Perfect balance of performance and power efficiency.

6. Limitations of 28nm

- Planar scaling limits – Couldn’t shrink much further without new transistor designs.

- Leakage power – As transistors got smaller, leakage currents became harder to control.

- Performance plateau – Later nodes (16nm, 7nm, etc.) introduced FinFETs to overcome these issues.

7. The Legacy of 28nm

Even though newer nodes like 5nm and 3nm dominate high-performance chips, 28nm remains a workhorse node:

- Foundries still manufacture 28nm chips in high volume.

- It’s considered a “long-lived node” because of its affordability and maturity.

- Many companies choose 28nm for products that don’t need cutting-edge performance but require reliability and lower cost.

8. The Bottom Line

28nm technology represents a pivotal point in semiconductor history. It balanced scaling, cost, and performance in a way that made it one of the most widely adopted nodes ever. While it’s no longer at the bleeding edge, its continued use in automotive, IoT, and consumer electronics proves that innovation isn’t always about chasing the smallest nanometer number—it’s about finding the right fit.

Why 28nm Chips Still Matter

28nm semiconductor technology refers to the size of transistors used in chip manufacturing. Transistors are the tiny switches that are the core of modern electronics. Smaller transistors mean more can fit on a chip, increasing computing power while using less energy.

Though the 28nm process debuted over a decade ago in 2011, it remains incredibly important in the tech world. Here’s why:

It Strikes a Balance

Modern chips boasting 5nm or 7nm technology are the pinnacle of performance, but they’re also very expensive to manufacture. This is where 28nm shines. It offers a great balance between:

- Performance: 28nm is powerful enough for many everyday devices, including smartphones and smart home products.

- Cost: Manufacturing these chips is much more affordable than the latest cutting-edge processes.

- Energy Efficiency: 28nm chips are less power-hungry than older technologies, which is important for battery-powered devices.

Versatility Across Industries

28nm technology isn’t just about cost-cutting. Here’s a snapshot of the different industries relying on it:

| Industry | Example Applications |

|---|---|

| Automotive | Sensors, driver assistance systems, infotainment units |

| Consumer Electronics | Smart TVs, appliances, wearables |

| Networking & Connectivity | Routers, modems, IoT devices |

| Industrial | Robotics, manufacturing equipment, control systems |

The Future of 28nm

28nm isn’t going away anytime soon. The world faces chip shortages, and the cost of building cutting-edge fabrication plants is astronomical. With its balance of performance and affordability, 28nm will continue to power a huge range of essential devices.

Key Takeaways

- 28nm technology maintains significance in the semiconductor industry due to its cost-efficiency and adaptability to various applications.

- Continuous improvements in 28nm design and manufacturing processes have extended its lifecycle.

- The integration of new features and ecosystem compatibility sustains the market position of 28nm process technology.

Advancements in 28nm Technology

The constant push for better performance and energy efficiency drives advancements in semiconductor technology. Notably, 28nm technology has seen significant improvements, particularly through the adaptation of high-k/metal gate processes and the active roles of foundries in innovation.

Developments in High-K/Metal Gate Process

High-k/metal gate technology represents a leap in semiconductor manufacturing. It helps to reduce power leakage and enhance device performance. TSMC, a leading foundry, adopted this method for their 28nm chips. They integrated high-k dielectrics with metal gate electrodes to improve transistor performance. This allows for chips that are faster and more power-efficient than earlier generations.

Role of Foundries in Innovation

Foundries like TSMC, UMC, and SMIC play a crucial role in advancing 28nm technology. Their investment in R&D and capacity expansion supports a wide range of specialty technologies. These companies, spread across regions such as Taichung, Korea, Japan, and China, have continuously evolved their 28nm processes. The development ensures products meet the growing demand for high performance with lower power consumption. They offer comprehensive 28nm process portfolios, enabling the creation of eco-friendly and energy-saving products.

28nm Market Dynamics and Applications

The 28nm process remains significant for various industries due to its balance between cost and performance. It continues to meet the demands of sectors that do not require the latest technology but prioritize reliability and power efficiency.

Demand in Key Sectors

Interest in the 28nm process technology is strong in areas such as consumer products, automotive, and industrial IoT. These sectors require high-performance semiconductors that offer a good balance of power efficiency and cost. In the automotive industry, for instance, 28nm chips are used in sensors and power management systems. Smartphones and other consumer products that need high-quality FPGA and microcontrollers also rely on this node.

Comparing 28nm with Adjacent Nodes

When looking at nodes like 22nm or the more advanced FinFET technologies, 28nm offers a compelling option for products that do not demand ultra-low power (22ULP) or the utmost processing speeds. The 28nm process provides an adequate supply for current market needs at a more affordable price point. Compared to 22nm, 28nm technology is well-established, which translates to less risk and more stable manufacturing capabilities for semiconductor foundries.

Frequently Asked Questions

The following frequently asked questions cover core aspects of 28nm technology in chip manufacturing. Here, we aim to clarify the technology’s benefits, ways to extend its utility, cost factors, common applications, limitations, and its ongoing evolution.

What are the benefits of using 28nm technology in chip manufacturing?

28nm technology strikes a balance between cost and performance in making chips. It offers higher speed and power efficiency compared to older, larger nodes while avoiding the higher costs of more advanced, smaller nodes.

How can the lifespan of 28nm chips be extended for industrial use?

To extend the life of 28nm chips, manufacturers can focus on improving design techniques. They can update chip architectures or employ new materials that reduce wear and power consumption.

What are the cost considerations when producing 28nm semiconductor devices?

Costs for 28nm devices include raw materials, fabrication, and development. Staying with 28nm technology avoids the high initial costs and complexities associated with transitioning to smaller and more advanced process nodes.

In what applications are 28nm chips most commonly utilized?

Chips at 28nm are common in applications where the balance of power, performance, and cost is critical. These include CPUs and GPUs for consumer electronics and networking equipment.

What are the limitations of 28nm technology when compared to more advanced nodes?

The 28nm node has limits in transistor density and power efficiency when set against smaller process nodes. As technologies advance, these limitations can affect performance in comparison to more modern solutions.

How has the production of 28nm technology evolved to remain competitive?

The production of 28nm chips has evolved through design innovation and process improvement. Manufacturers optimize existing equipment and techniques to push the boundaries of what 28nm can achieve.