The 14nm FinFET technology marks a major advancement in semiconductor manufacturing. This technology uses fin field-effect transistors, which are non-planar transistors designed to improve performance and reduce power consumption. Companies like Intel, TSMC, Samsung, and IBM have adopted this technology to create faster, more efficient chips.

14nm FinFET technology emerged around 2014 and has been central in continuing the trend predicted by Moore’s Law. The key advantage of the 14nm process is its ability to pack more transistors into a single chip, boosting processing power while consuming less energy. This has paved the way for more powerful and energy-efficient devices across various sectors.

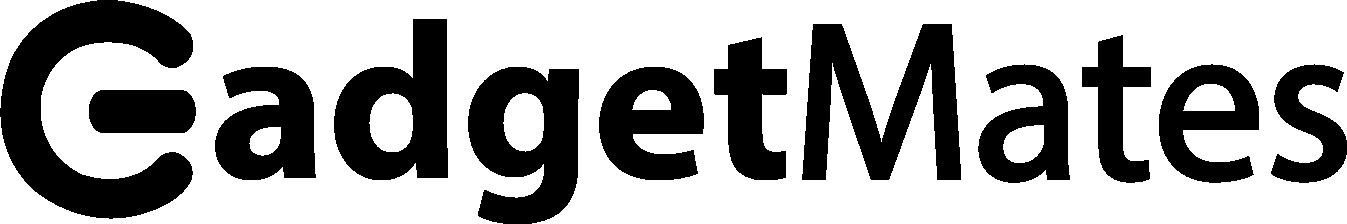

Intel’s implementation of 14nm FinFET has led to significant improvements in transistor performance and density. Taller, thinner, and more closely spaced fins characterize this technology, which enhances both speed and efficiency. This breakthrough continues to influence the industry, driving innovation in semiconductor technology.

14nm FinFET Technology: Overview and Key Facts

14nm FinFET technology is a significant milestone in semiconductor manufacturing, marking a shift from planar transistors to 3D Fin Field-Effect Transistors (FinFETs). It enables improved performance, power efficiency, and scaling for advanced integrated circuits, especially CPUs, GPUs, and SoCs.

What is FinFET Technology?

- FinFET stands for Fin Field-Effect Transistor.

- Unlike traditional planar transistors, FinFETs use a 3D “fin”-shaped structure that rises above the substrate.

- This 3D structure wraps the gate around the fin on three sides, improving control over the channel.

- Result: Reduced leakage current, better switching speed, and lower power consumption.

Why 14nm?

- 14 nanometer (nm) refers to the semiconductor process node size, roughly indicating the smallest half-pitch of the transistor gate.

- 14nm was a key node after 22nm and 16/20nm planar technologies.

- It represents a leap in transistor density and efficiency, enabling more transistors per chip.

Key Advantages of 14nm FinFET Technology

| Advantage | Explanation |

|---|---|

| Improved Performance | Faster transistor switching speeds |

| Lower Power Consumption | Reduced leakage current and dynamic power |

| Higher Density | More transistors per unit area, enabling complex chips |

| Better Thermal Characteristics | Less heat generation and better heat dissipation |

| Compatibility | Compatible with bulk silicon and SOI substrates |

Applications of 14nm FinFET Technology

- CPUs: Intel’s 14nm process powered many generations of Core processors.

- Mobile SoCs: Qualcomm Snapdragon and Samsung Exynos chips have used 14nm FinFET.

- GPUs: Nvidia and AMD leveraged 14nm FinFET for improved graphics performance.

- IoT and Low-Power Devices: Enhanced efficiency benefits battery-powered devices.

Manufacturing Challenges

- Complex 3D structure requires advanced lithography and etching techniques.

- Managing variability and defects is critical at such small scales.

- High manufacturing costs compared to older planar nodes.

Industry Examples

- Intel: Introduced 14nm FinFET in 2014 with Broadwell CPUs.

- Samsung: Used 14nm FinFET for Exynos and other chipsets.

- TSMC: Offered 16nm/14nm FinFET processes for various clients.

Summary Table

| Feature | Details |

|---|---|

| Technology Type | 3D Fin Field-Effect Transistor (FinFET) |

| Process Node Size | 14 nanometers |

| Benefits | Higher speed, lower power, increased density |

| Key Users | Intel, Samsung, Qualcomm, AMD, Nvidia |

| Applications | CPUs, GPUs, mobile SoCs, IoT devices |

Further Reading

- Intel’s 14nm Technology Overview

- Comprehensive Review of FinFET Technology (MDPI)

- 14nm Process Explained (Everything Explained Today)

Tiny Transistors, Giant Leaps in Computing

What is 14nm FinFET Technology?

In simple terms, 14nm FinFET is a way to make tiny transistors for computer chips. These transistors are the building blocks of processors, and the smaller they are, the more you can fit on a chip. This leads to faster, more powerful, and more energy-efficient devices.

How Does It Work?

Traditional transistors were flat, like pancakes. FinFET transistors stand upright, like fins, which allows for better control of current flow. This results in less power leakage and improved performance.

Advantages of 14nm FinFET

- Increased Performance: Smaller transistors mean faster switching speeds, leading to better overall performance.

- Lower Power Consumption: FinFET technology reduces power leakage, resulting in longer battery life and cooler-running devices.

- Higher Transistor Density: More transistors on a chip means more processing power in the same space.

Applications

14nm FinFET technology has found its way into various devices, including:

- High-Performance Processors: Used in laptops, desktops, and servers to deliver fast and efficient computing.

- Smartphones and Tablets: Enables powerful mobile devices with longer battery life.

- Graphics Cards: Powers high-end graphics for gaming and professional applications.

Industry Adoption

Major chip manufacturers like Intel, Samsung, and TSMC have adopted 14nm FinFET technology. It played a crucial role in the evolution of computing devices, paving the way for even smaller and more powerful chips.

14nm FinFET: A Technical Overview

| Feature | Description |

|---|---|

| Transistor Structure | 3D FinFET (Fin Field-Effect Transistor) |

| Process Node | 14 nanometers (nm) |

| Advantages | Increased performance, lower power consumption, higher transistor density |

| Applications | High-performance processors, smartphones, tablets, graphics cards |

| Manufacturers | Intel, Samsung, TSMC |

Key Takeaways

- 14nm FinFET uses advanced transistor design for better performance.

- The technology allows more transistors in a smaller area, boosting efficiency.

- Adopted by major companies, it has driven semiconductor innovation.

Fundamentals of 14nm FinFET Technology

14nm FinFET technology represents a significant advancement in semiconductor manufacturing. It offers superior performance, efficiency, and scaling compared to previous nodes.

Evolution and Significance

14nm FinFET technology emerged as a successor to the 22nm node. Developed by companies like Intel and AMD, it uses a 3D transistor structure. This allows better control over the electrical current. The transition to 14nm nodes provided an increase in performance and reduction in power consumption.

Intel, with its Broadwell and Xeon microprocessors, showcased the benefits of this technology. The move to FinFET marked a shift away from planar CMOS. It represented a significant development for the industry, pushing forward Moore’s Law and enabling the production of more efficient chips.

Architectural Features

The core of 14nm FinFET technology lies in its 3D structure. The transistor has a thin fin that protrudes from the silicon. This fin forms the conductive channel. The gate wraps around the fin on three sides, enhancing control over the channel.

Key parameters include the Fin Pitch, Height, Width, and Gate Length. These features improve the ON/OFF control, reducing leakage current. The technology also incorporates double patterning for precise pattern definition. Performance parameters such as F_t/F_max are crucial for analog and RF applications.

Manufacturing Processes

Manufacturing at the 14nm scale requires advanced techniques. Lithography Process like immersion lithography and double patterning are vital. These methods help in accurately defining the small structures.

Integrated circuits at this node often use SOI (Silicon on Insulator) substrates. Copper interconnects ensure rapid signal transmission. Double patterning involves using a spacer to define feature sizes more precisely. The 14nm process managed complexities like angular position and spacer width to achieve the desired transistor dimensions.

Frequently Asked Questions

14nm FinFET technology represents a significant advancement in semiconductor manufacturing. It offers improved performance, power efficiency, and transistor density compared to previous generations.

What are the characteristics of 14nm FinFET technology compared to previous generations?

14nm FinFET technology uses 3D transistors which are smaller and faster than 2D planar transistors. This technology also reduces power leakage and allows for denser packing of transistors on a chip.

How does the 14nm FinFET manufacturing process impact semiconductor performance?

The 14nm FinFET process enhances low voltage performance and reduces power consumption. Tri-gate transistors in this technology offer better control over current flow, improving overall chip performance.

Can you explain the advantages of 14nm FinFET over larger nodes for processor fabrication?

14nm FinFET technology delivers up to a 50% power reduction and a 40-50% performance increase compared to larger nodes like 28nm. This means faster and more energy-efficient processors.

In terms of power efficiency and transistor density, how does 14nm FinFET technology advance microchip design?

14nm FinFET transistors enable higher transistor density, reducing chip size. They also operate at lower voltages, enhancing power efficiency which is crucial for mobile devices and large data centers.

What are the technical challenges associated with the production of 14nm FinFET semiconductors?

Producing 14nm FinFET semiconductors involves challenges like double patterning and ensuring correct placement and routing. There are strict process rules that need to be followed to ensure proper functionality and yield.

How do 14nm FinFET transistors contribute to the scaling of integrated circuits?

Scaling to 14nm FinFET transistors helps keep up with Moore’s Law. These transistors allow for more functionality within a smaller area, contributing to the advancement of integrated circuits and enabling new applications like IoT and AI.