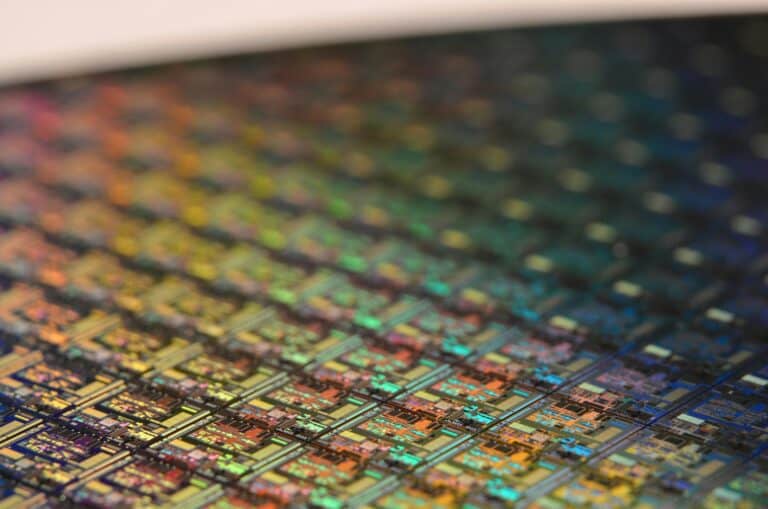

Intel’s journey into the world of semiconductor manufacturing is a tale of innovation and expansion. With a global footprint, Intel’s foundry locations are pivotal to the tech industry. They’re where the magic happens, turning silicon into the chips that power everything from computers to smartphones.

As the tech landscape evolves, Intel’s foundries stand at the forefront of change. These facilities are not just factories; they’re hubs of high-tech engineering and manufacturing prowess. With investments in cutting-edge technology, Intel is pushing the boundaries of what’s possible in chip production.

Intel’s Strategic Expansion: Building a Global Foundry Network

Intel is investing heavily in expanding its chip manufacturing capacity across the globe. This move is designed to improve the company’s production capabilities and strengthen its presence in key markets worldwide.

Expanding Footprint in the United States

Intel is making significant investments in its foundry operations within the United States:

- Arizona Expansion: Existing foundries in Arizona are at the forefront of chip production for Intel. These facilities utilize the latest manufacturing processes.

- Ohio Mega-Site: Announced as a critical part of Intel’s IDM 2.0 strategy, this new location in Ohio will dramatically increase Intel’s manufacturing capacity within the US. This site will also host Intel Foundry Services, allowing Intel to produce chips for other companies and expand its role in the semiconductor ecosystem.

Intel’s Presence in Europe

Europe is another key region for Intel’s global expansion plans. The company has several facilities across the continent that are essential for manufacturing, operations, and research & development:

- Ireland Plant: This Irish facility plays a pivotal role in Intel’s manufacturing network. This location is also a hub for cutting-edge research, driving technological innovation.

Potential Locations in Asia

Intel is actively exploring options to expand its foundry presence in Asia. This would create stronger collaboration with tech hubs in the region and improve supply chain resilience:

| Potential Location | Possible Advantages |

|---|---|

| Malaysia | Existing manufacturing relationships, skilled workforce |

| India | Large pool of engineering talent, government incentives |

| Taiwan | Proximity to established semiconductor ecosystem |

Why Global Expansion Matters

Intel’s worldwide expansion of foundry locations offers several key benefits:

- Increased Production Capacity: More foundries mean Intel can produce more chips, meeting the rising global demand for semiconductors.

- Supply Chain Resilience: Having foundries in different regions helps mitigate risks from disruptions like natural disasters or geopolitical events.

- Technological Collaboration: Expanding into tech hubs promotes collaboration, innovation, and the sharing of expertise within the industry.

Key Takeaways

- Intel’s foundry locations across the USA, Europe, and Asia are crucial to its operations, serving not only as manufacturing hubs but also as centers for innovation and technological advancements.

- The establishment of new foundry sites, such as the one in Ohio, align with Intel’s IDM 2.0 strategy to enhance manufacturing capacity and drive technology advancement, indicating Intel’s commitment to leadership in the semiconductor industry.

- Intel’s strategic presence in Asia, particularly in Taiwan, Vietnam, and China, plays a pivotal role in tapping into local expertise and staying at the forefront of the fast-paced tech industry, thereby shaping the future of chip technology.

- The spread of Intel’s foundries in key tech hubs globally allows the company to meet the growing demand for advanced chips, vital for powering modern devices and pushing the envelope in chip performance and efficiency.

- Future prospects for Intel involve heavy investment in cutting-edge technology and expansion of foundry locations to maintain competitiveness and leadership in the semiconductor market, amidst challenges such as mastering new technologies and financial risks associated with high investments.

- Recent developments, including the passage of the CHIPS Act and Intel’s IDM 2.0 strategy, highlight the company’s ongoing efforts to innovate and adapt in a fiercely competitive industry, aiming for a leading role in the next wave of chip technology innovation.

Intel’s Foundry Locations in the USA

Intel, a giant in chip making, has several key foundry locations across the United States. These sites are crucial for its operations, not just as manufacturing hubs but also as centers for innovation and technological advancements. They play a vital role in pushing the boundaries of what’s possible in the semiconductor industry.

One of the most notable Intel foundry locations is in Arizona. This site is at the forefront of chip production, utilizing some of the most advanced manufacturing processes available. It’s a place where precision meets the cutting edge of technology to produce chips that power countless devices around the world.

In addition to Arizona, Intel is expanding its foundry capabilities with a new location in Ohio. Announced as part of Intel’s IDM 2.0 strategy, this site aims to bolster Intel’s manufacturing capacity in the US. It’s not just about making more chips; it’s about advancing the technology behind them. The Ohio site will host Intel Foundry Services, which means it will also produce chips for other companies, expanding Intel’s role in the global tech ecosystem.

The establishment of the Ohio foundry is a significant move. It’s a clear sign that Intel is doubling down on its commitment to not only retain its leadership in the chip industry but also to drive innovation and growth. By building this facility, Intel is positioning itself to meet the increasing demands of the tech world and to contribute to the overall health of the semiconductor industry.

Intel’s foundry locations in the USA are more than just factories. They are beacons of technological advancement and innovation. As the company continues to invest in these sites, it strengthens its capacity to lead in a highly competitive market.

Intel’s Foundry Locations in Europe

Intel has been expanding its footprint across the globe, and Europe is no exception. This continent hosts key sites that are pivotal for Intel’s operations, manufacturing, and research and development efforts. The company’s commitment to innovation and technology shines through its European foundry locations.

One major hub in Europe is the plant in Ireland. This site is crucial for Intel’s production network. It’s not just a site for chip manufacturing; it’s also a center for cutting-edge research. Intel pours significant resources into this location to keep it at the forefront of technology.

In Germany, Intel’s focus is on innovation and development. The sites here contribute to research in computing technologies. They’re part of Intel’s broader strategy to lead in the tech industry, not just by making chips but also by developing new tech solutions.

Poland is another important spot on the map for Intel in Europe. This location emphasizes software development. It’s home to teams working on a range of projects, from security technologies to solutions for the Internet of Things (IoT). Intel’s presence in Poland highlights the company’s approach to go beyond hardware and venture into software innovations.

Intel’s foundry locations in Europe are not just about manufacturing. They are hubs of innovation, research, and development. Each site plays a unique role in Intel’s global strategy. These locations help Intel stay ahead in the tech game, pushing boundaries and exploring new possibilities.

Intel’s Foundry Locations in Asia

Intel has made big moves in Asia, setting up foundry locations to keep up with the fast-paced tech world. In Asia, where the tech industry booms, Intel’s presence marks a significant step. They’re not just playing the game; they are setting the rules with state-of-the-art facilities.

One of Intel’s key locations is in the heart of the tech world – Taiwan. This spot is crucial because Taiwan is a giant in chip manufacturing. Here, Intel works on some of its most advanced chips. It’s all about staying ahead and making chips that power everything from computers to gadgets we use every day.

Next up, let’s talk about Vietnam. Intel’s facility in Vietnam is massive and plays a vital role in assembling and testing. This location helps Intel make sure that their chips are ready for action. They check each chip’s performance and durability before it goes out into the world.

But it’s not just about making chips. In China, Intel focuses on research and development, too. This location is where Intel’s experts work on new ideas and technologies. They’re always looking for ways to make chips faster, smaller, and more powerful.

Intel’s strategic choice of locations in Asia shows they’re serious about leading in chip technology. By spreading across Taiwan, Vietnam, and China, Intel taps into local expertise and positions itself at the forefront of innovation. They’re not just making chips; they’re shaping the future of technology.

Importance of Intel’s Foundry Locations in the Tech Industry

Intel’s foundry locations hold a crucial spot in the tech industry. These places are where the company makes its chips. Chips are tiny parts that make gadgets like phones, computers, and even cars work faster and better. With foundries spread out in Asia, particularly in Taiwan, Vietnam, and China, Intel is in a strong position. These spots are at the center of tech manufacturing.

Having foundries in these key locations allows Intel to make a lot of chips and keep up with demand. Today, every new device needs advanced chips to run apps smoothly and handle big tasks. Intel’s foundries use cutting-edge technology to make chips that meet these needs. This is no small feat. The company spends a lot of money to stay ahead. In fact, some machines used in chip making can cost about $340 million each.

Being close to major tech hubs in Asia is another advantage for Intel. This helps the company work closely with other tech firms. They can share ideas and resources. This close working relationship speeds up the making of new and better chips.

However, it’s not just about making chips. Intel is also big on research and development. This means they are always trying to find new ways to make chips work better. Think of it like adding more horsepower to a car. More power means a faster and smoother ride. Intel wants the same thing for gadgets. By pushing the limits on how chips are made and how well they perform, Intel is shaping the future of tech.

The tech industry moves fast. Being able to make lots of high-quality chips quickly is key for Intel. This lets them respond to new trends and needs. With their strategic foundry locations and a focus on innovation, Intel is geared up to lead in the chip technology race.

Future Prospects of Intel’s Foundry Locations

Intel’s journey into the future of chip manufacturing is both challenging and promising. The company aims to bounce back by investing heavily in high-tech machines and expanding its foundry locations. This strategy could play a critical role in the tech landscape.

At the heart of Intel’s plan is the acquisition of cutting-edge equipment, specifically a next-generation machine bought for an average of $340 million. Learning to use this advanced tool will take time but is crucial for staying competitive. Intel’s commitment is seen in its willingness to adopt new technologies to improve chip production.

Expansion is also on the horizon. Intel’s strategy involves spending big on new foundry locations. This move is not just about making more chips. It’s about getting closer to where the tech action is, especially in Asia. The proximity to tech hubs is vital for collaboration and staying ahead in the game.

Recent Developments and Challenges

- The passage of the CHIPS Act signals government support for the semiconductor industry, promising a boost for companies like Intel.

- The challenge for Intel lies not just in expansion but also in mastering new technologies. Competitors like TSMC and Samsung are already ahead in some areas.

- Intel’s CEO, Gelsinger, has outlined a bold IDM 2.0 strategy, focusing on both in-house chip production and foundry services for other companies. This dual approach could redefine Intel’s role in the tech world.

Financials and Market Position

Investing billions into new technologies and foundries is a gamble that could either set Intel back on top or strain its resources. Market analysts have expressed concern over the company’s spending and the risks involved. However, Intel’s leadership is banking on the long-term benefits of these investments.

Intel’s future in the foundry landscape hinges on successfully navigating these challenges. By pressing forward with its expansion and technology adoption plans, Intel aims to not just compete but lead in the next wave of innovation in chip technology.

Conclusion

Intel’s bold steps toward expanding its foundry locations and investing in state-of-the-art technology showcase its determination to stay at the forefront of the semiconductor industry. The company’s efforts to establish a stronger presence in Asia and its significant financial commitment highlight its strategy to not only compete but lead in the global chip manufacturing arena. With the IDM 2.0 strategy at its core, Intel is poised to navigate the challenges posed by rivals and market skepticism. Their focus on innovation and in-house production sets a promising path for the future, aiming to secure Intel’s position as a leader in the next wave of chip technology advancements.

Frequently Asked Questions

What is Intel investing in to stay competitive in chip manufacturing?

Intel is investing in cutting-edge technology, including a $340 million next-generation tool, to enhance its competitiveness in the chip manufacturing industry. This investment highlights the company’s commitment to leading in technological innovation.

Why is Intel expanding its foundry locations?

Intel is expanding its foundry locations, particularly in Asia, to foster better collaboration and innovation within tech hubs. This strategic move aims to improve Intel’s manufacturing capabilities and its presence in key markets.

How does Intel’s IDM 2.0 strategy impact its position in the chip industry?

Intel’s IDM 2.0 strategy, which emphasizes in-house production and foundry services, aims to redefine the company’s position in the chip industry. By focusing on internal manufacturing and offering foundry services to others, Intel seeks to gain a competitive edge over rivals like TSMC and Samsung.

Are market analysts concerned about Intel’s financial investments?

Yes, some market analysts express concerns about Intel’s significant financial investments in technology and expansion. Despite these concerns, Intel remains optimistic about the long-term benefits of these investments in securing its leadership in the next wave of chip technology innovation.

What are the long-term benefits Intel anticipates from its investments and strategy?

Intel anticipates that its investments in cutting-edge technology and its strategic expansion of foundry locations will secure its leadership in the next wave of chip technology innovation. The company believes these efforts will enhance its competitive position and foster long-term growth in the industry.