Water cooling systems offer superior performance and quieter operation compared to traditional air cooling. But what exactly is swirling around inside your PC’s tubes? We’re talking about liquid coolant, which can be composed of many different things and water isn’t always the sole liquid used. Here’s a list of different types of coolants:

Distilled Water: The Gold Standard

Distilled water is the most commonly recommended liquid for PC water cooling systems. It offers excellent thermal properties and is safe for your components when used properly.

Why Distilled Water Works Best:

- Excellent heat capacity: Water has one of the highest specific heat capacities of common liquids

- Low electrical conductivity: Pure distilled water is non-conductive, reducing risk of shorts

- No impurities: Free from minerals and contaminants that could cause buildup or corrosion

- Cost-effective: Readily available and inexpensive

Important: Never use tap water, as it contains minerals, chlorine, and other impurities that can cause corrosion, electrical conductivity issues, and microbial growth over time (source: Fresh Water Systems).

Commercial Coolants

Many manufacturers offer specialized PC coolants that combine distilled water with additives:

Common Additives Include:

- Biocides: Prevent algae and bacterial growth

- Anti-corrosion agents: Protect metal components from oxidation

- Anti-foaming agents: Reduce air bubbles in the system

- Dyes: For aesthetic purposes (colored coolants)

Popular Brands:

- EK-CryoFuel

- Corsair XL Series

- Thermaltake TT Premium

- Primochill Vue/Liquid Utopia

Glycol-Based Mixtures

For extreme conditions or specialized applications, glycol-water mixtures may be used:

Types of Glycol:

- Ethylene Glycol (EG): Commonly used in automotive applications

- Propylene Glycol (PG): Food-safe alternative

These mixtures provide freeze protection and can handle wider temperature ranges, but they have lower thermal conductivity than pure water (source: Tark Solutions).

What NOT to Use

Avoid These Liquids:

- Tap water: Contains minerals and chemicals that cause problems

- Deionized water only: Can become corrosive over time without additives

- Automotive coolants: Often contain additives harmful to PC components

- Alcohol-based solutions: Can damage seals and tubing

Properties of an Ideal PC Coolant

When selecting a coolant, look for these characteristics (source: Overclockers):

- High specific heat capacity: Better heat absorption

- Low electrical conductivity: Safety for components

- Chemical stability: Won’t break down over time

- Low viscosity: Easy pumping and flow

- Non-corrosive: Protects metal components

- Antimicrobial properties: Prevents biological growth

Maintenance Considerations

Regular Maintenance Required:

- Change coolant every 6-12 months (depending on type)

- Monitor for discoloration or particles

- Check pH levels if using custom mixtures

- Clean components during coolant changes

Recommendations by Use Case

For Beginners:

- Pre-mixed commercial coolants with biocides and anti-corrosion additives

- Brands like EK-CryoFuel or Corsair XL Series

For Enthusiasts:

- Distilled water + separate additives for custom mixing

- Allows for precise control over coolant properties

For Show Systems:

- Colored commercial coolants with UV-reactive dyes

- Note: Some dyes can stain components over time

Conclusion

Distilled water remains the foundation of most PC cooling liquids due to its excellent thermal properties and safety profile. Whether you choose pure distilled water with additives or a commercial pre-mixed solution, avoid tap water and automotive coolants. The key is selecting a coolant that balances thermal performance, component protection, and maintenance requirements for your specific setup (source: 10PCG).

Regular maintenance and proper coolant selection will ensure your water cooling system operates efficiently while protecting your valuable PC components.

| Liquid Type | Description | Pros | Cons |

|---|---|---|---|

| Distilled Water: | The purest option, offering excellent thermal conductivity and low electrical conductivity (safe for electronics). | Affordable, readily available, good for beginners. | Prone to algae and bacteria growth, requires regular maintenance. |

| Deionized Water: | Similar to distilled water but with minerals and ions removed, further reducing conductivity. | Slightly better performance than distilled water, longer lifespan. | More expensive than distilled water. |

| Ethylene Glycol (EG): | A common coolant additive, lowers the freezing point and raises the boiling point, preventing damage in extreme temperatures. | Provides freeze/boil protection, improves heat transfer, longer lifespan. | Toxic if ingested, requires careful handling and disposal. Not compatible with all materials. |

| Propylene Glycol (PG): | A non-toxic alternative to EG with similar properties, good for environmentally conscious users. | Less toxic than EG, safer for pets and children. | Slightly lower performance than EG, more expensive. |

| Premixed Coolants: | Convenient blend of water, additives, and corrosion inhibitors, ready to use. | Easy to use, no mixing required, long shelf life. | Can be expensive, limited customization, may contain dyes that clog tubing. |

Choosing the Right Liquid

The best liquid for you depends on your needs and budget. Distilled/deionized water is ideal for budget-conscious users, while EG or PG offer better freeze/boil protection for harsh environments. Premixed coolants are convenient but less customizable. Always consult your system’s manual and component compatibility before choosing a liquid.

Bonus Tip: Consider using colored coolants for a visually appealing setup, but be aware they can clog tubing and require more maintenance.

Remember, water cooling requires proper maintenance to prevent corrosion and ensure optimal performance. Regularly clean your loop and replace the coolant as needed.

Overview of Liquid Cooling Systems

Liquid cooling systems serve as a crucial solution for dissipating heat from high-performance electronics, specifically CPUs and GPUs, which can run exceedingly hot.

Fundamentals of Liquid Cooling

At its core, liquid cooling utilizes a fluid, primarily water or a specialized coolant, to absorb and transfer heat away from critical components like the CPU (Central Processing Unit) and GPU (Graphics Processing Unit). A liquid cooling system is typically more efficient than air cooling because liquids conduct heat better than air. This method involves a continuous cycle where the heated liquid is moved away from the components, cooled down, and then circulated back to absorb more heat.

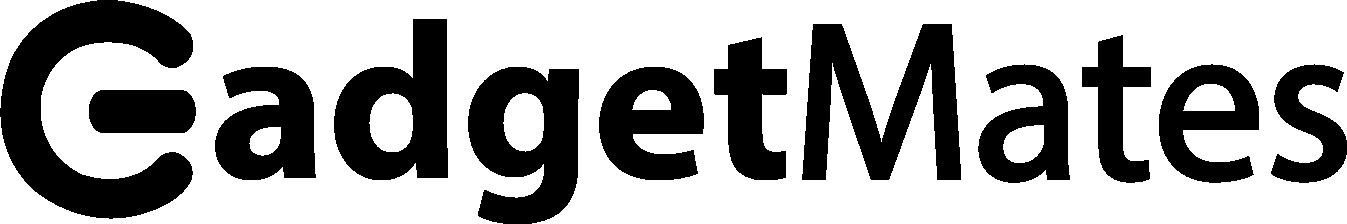

Components of a Water Cooling Setup

Each water cooling system includes several key parts:

- Water Block: This attaches directly to the CPU or GPU and acts as the contact point for heat absorption.

- Radiator: It functions as a heat exchanger where the heat absorbed by the liquid is dissipated into the air, often aided by attached fans.

- Pump: This component propels the coolant through the system’s tubing, ensuring consistent liquid flow.

- Reservoir: This holds the excess cooling fluid and makes it easier to fill or refill the system.

- Tubing: These are the channels through which the coolant travels between the various components.

A water cooling setup combines these components to manage the temperatures of high-performance computers, ensuring they run smoothly and reliably.

What Liquid Is Inside An AIO Cooler?

The liquid inside an AIO (All-in-One) cooler is typically not just pure water, but a premixed coolant specifically designed for computer liquid cooling systems. This premix offers several advantages over plain water:

- Freeze/boil protection: Protects your system from damage caused by freezing or boiling temperatures. This is especially important in colder climates or if your PC operates in extreme conditions.

- Corrosion inhibition: Reduces the risk of corrosion on your radiator, pump, and other components, ensuring longer lifespan for your AIO.

- Biocide protection: Inhibits the growth of algae and bacteria in the loop, maintaining cleanliness and optimal performance.

- Improved heat transfer: Some premixes contain additives that can slightly improve heat transfer compared to pure water.

While the exact composition of the premix varies between brands and models, they generally consist of:

- Distilled or deionized water: As the base liquid for its superior thermal conductivity.

- Ethylene glycol (EG) or propylene glycol (PG): For freeze/boil protection and improved heat transfer. PG is a non-toxic alternative to EG, but slightly less efficient.

- Corrosion inhibitors: Protect your components from corrosion.

- Biocides: Prevent algae and bacteria growth.

- Dyes: Some premixes contain dyes for aesthetic purposes, but these require extra care to avoid clogging the loop.

Important Note: Regardless of the premix used, remember that the liquid inside an AIO is not typically intended for consumption. It may contain additives that are harmful if ingested.

Here are some additional points to consider:

- Premixes offer convenience: No need to mix your own coolant, saving you time and hassle.

- Limited customization: You can’t adjust the concentration of individual components like with custom loop coolants.

- Cost: Premixes can be more expensive than buying and mixing your own coolant.

Overall, the premixed coolant in an AIO is a good choice for most users who want a low-maintenance and reliable solution for their liquid cooling system. However, if you want more control over the coolant composition or have a specific need for custom properties, you can explore building your own custom loop.

Types and Properties of Coolants

When building a water cooling system for electronics or engines, choosing the right type of liquid—or coolant—is a big deal. Water is the essence of all coolants, and it’s prized for its high thermal conductivity and heat capacity. But we don’t just use tap water; distilled water and deionized water are preferred because they lack mineral content that might cause corrosion or build-up in cooling systems.

However, water isn’t perfect. It can conduct electricity, which is risky for electronic components. To reduce electrical conductivity, additives like biocides and corrosion inhibitors are introduced, also prolonging the life of the coolant. Unique to some coolants are dyes for aesthetic appeal, but remember, these are for looks and not performance.

For lower freeze points and higher boiling points, glycols like ethylene glycol and propylene glycol are added. Ethylene glycol is efficient but toxic, so when safety matters, propylene glycol, a non-toxic alternative, is better. Both enhance the boiling and freeze points of water, allowing the coolant to function effectively in a wider range of temperatures.

Lastly, there’s the clear coolant, often used when clarity over color is preferred. Clear solutions facilitate checking for impurities and flow issues without the distraction of color.

| Coolant Type | Pros | Cons |

|---|---|---|

| Distilled Water | High thermal conductivity, non-toxic | Can cause corrosion, conducts electricity |

| Deionized Water | Pure, less mineral content | Conducts electricity, more expensive |

| Ethylene Glycol | Low freeze point, high boiling point | Toxic, requires careful handling |

| Propylene Glycol | Non-toxic, wide temperature range | Less thermal conductivity than ethylene glycol |

| Clear Coolant | No dyes, easy to spot impurities | Varies based on additive composition |

In summary, the best coolant balances a low freeze point, high boiling point, safety, and minimal electrical conductivity. It’s crucial to match coolant properties with application requirements to protect your equipment and achieve optimum performance.

Cooling System Maintenance and Performance

Maintaining the right balance in a water cooling system ensures top-notch thermal management and peak performance. Over time, contaminants and corrosion can impair a system’s efficiency, making routine maintenance a necessity.

Ensuring Efficient Thermal Management

Effective thermal management hinges on the coolant’s heat capacity and its ability to flow smoothly through the system. Coolants like deionized water, which have high heat capacity, are very efficient in absorbing and transferring heat. However, the efficiency can diminish if the coolant’s viscosity is altered by temperature changes or impurities. To preserve an efficient thermal exchange, it’s important to check for any changes in the fluid’s properties over time. Regular system flushes and replacement of coolant can help maintain optimal performance.

- Clear out any debris or build-up to maintain flow and prevent clogs

- Monitor the coolant levels and top off as necessary to keep the system running smoothly

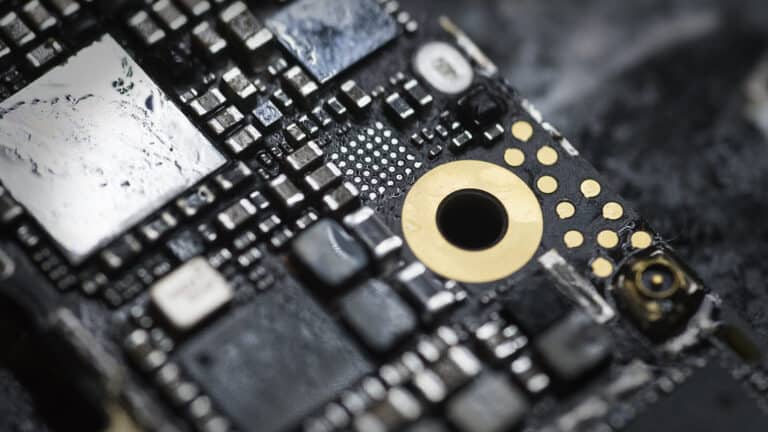

Mitigating Corrosion and Contamination

Corrosion and contamination can severely affect a cooling system’s health. The presence of oxygen, water, and metals can lead to oxidation and galvanic corrosion, which weaken the system’s components. Adding chemicals like corrosion inhibitors and biocides can prevent this damage and prolong the system’s life.

- Corrosion Inhibitors: Add to the coolant to create a protective layer on metal parts

- Biocides: Include in the coolant to prevent the growth of microorganisms

Furthermore, water contains calcium and magnesium, which can form scale or deposits that restrict flow. Regular water testing and treatment can prevent scale formation.

- Inspect for signs of corrosion during routine maintenance checks

- Use filtered or specially formulated coolants to reduce the risk of impurities and contaminants

By following these guidelines, you can ensure your liquid cooling system maintains efficiency and performance over time. Regular maintenance is key to preventing issues that can interfere with the optimal operation of your cooling setup.

Frequently Asked Questions

Choosing the right liquid for your PC water cooling system is crucial for optimal performance and longevity. This section aims to answer common questions regarding the best fluids to use, maintenance, and the differences between various cooling solutions.

What are the best fluids to use in a PC water cooling system?

The optimal choice for a PC water cooling system is often distilled water due to its purity and lack of conductive minerals. For enhanced protection against corrosion and biological growth, users sometimes mix distilled water with specialized coolants that include anti-corrosive and biocidal agents.

Can distilled water be used exclusively in water cooling loops?

Yes, distilled water can be used on its own in water cooling loops because it’s free from minerals and impurities. However, to guard against algae and microbial growth, the addition of a biocide is recommended.

What are the primary components of PC coolant?

PC coolant typically consists of distilled water mixed with additives such as biocides and anti-corrosive agents. These additives help to protect the cooling system from corrosion and biological contamination over time.

Is it necessary to use additives with distilled water in water cooling systems?

While not strictly necessary, additives improve the distilled water’s properties by preventing algae growth and metal corrosion within the loop. Without them, the system may require more frequent maintenance.

How frequently should the coolant be replaced in a liquid CPU cooler?

It’s advisable to replace the coolant in a liquid CPU cooler every 1-2 years to maintain the system’s cleanliness and performance. This frequency keeps the loop clear of potential build-ups that can impact cooling efficiency.

What are the differences between fluids used in AIO coolers and custom loop solutions?

Fluids in All-In-One (AIO) coolers are generally pre-mixed with additives and designed for long-term use without maintenance. Custom loop solutions, however, allow for a greater degree of customization, enabling users to mix their own coolant with preferred ratios of distilled water and additives to achieve specific performance and aesthetic goals.