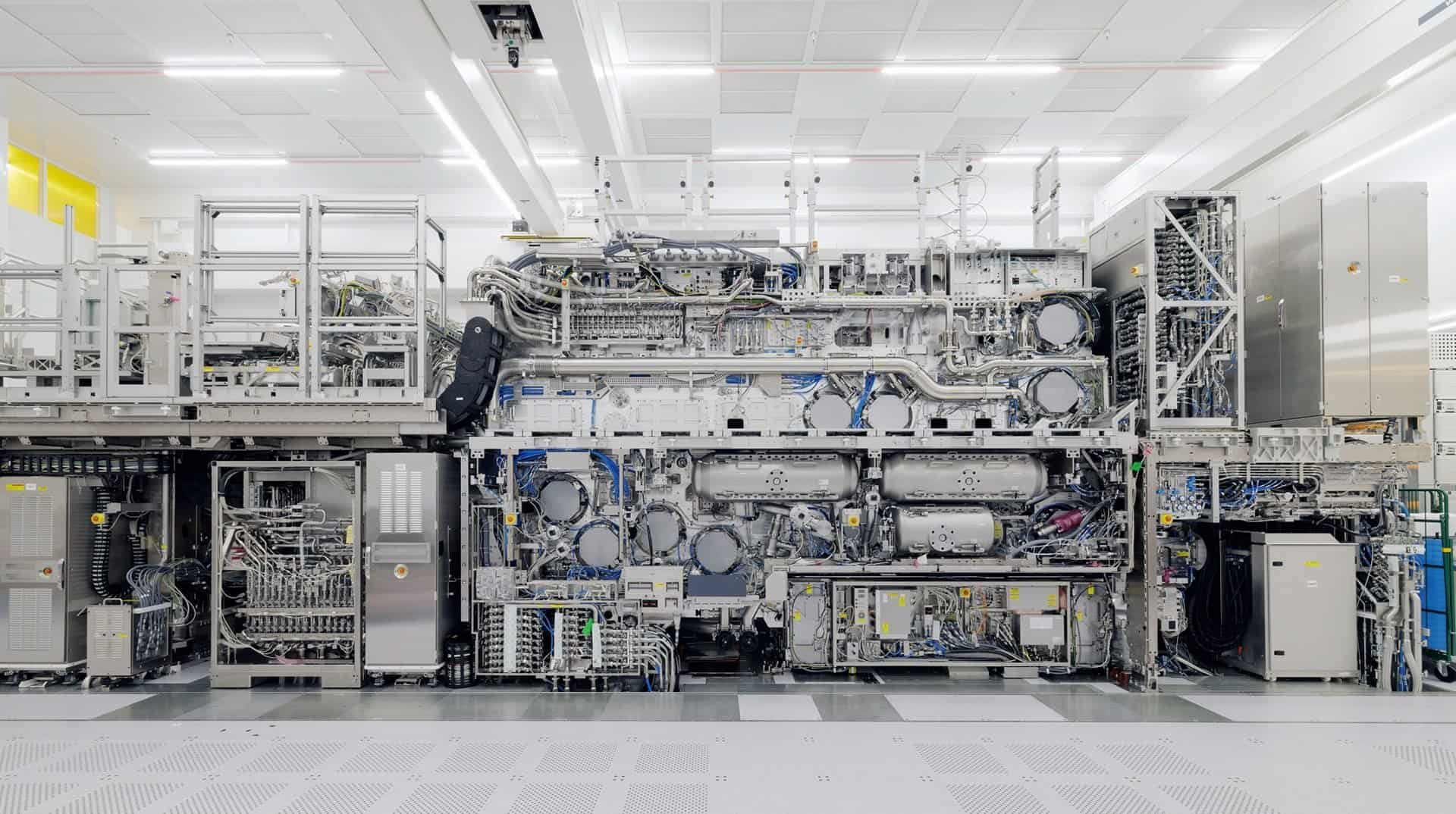

Intel and ASML have teamed up to bring the future of chip manufacturing to life, entering a historic phase in semiconductor manufacturing with the adoption of ASML’s High-NA EUV (Extreme Ultraviolet) lithography systems. After years of research and development, they’ve unveiled the TWINSCAN EXE5000, a game-changer in the world of tech. This system uses extreme ultraviolet (EUV) lithography, a fancy way of saying it can make chips smaller and more powerful than ever before.

The journey to this innovation wasn’t quick and it took almost a decade of hard work and smarts to get here. In December 2023, ASML shipped the first modules of this high-tech system to Intel. This move marks a big step forward. Intel plans to use this new machine for experiments first, before making lots of chips with it. This is big news for gadgets and devices, making them faster and smarter.

These next-generation tools are central to Intel’s 18A node, which is expected to deliver unprecedented transistor density, performance, and efficiency. Intel is the first company in the world to install and operate ASML’s EXE:5000/5200B High-NA EUV machines, marking a critical step toward reclaiming process leadership.

What is High-NA EUV?

- Numerical Aperture (NA): A measure of a lens system’s ability to capture light. Standard EUV scanners operate at NA = 0.33, while High-NA systems reach 0.55 NA, enabling finer resolution.

- Resolution improvement: Roughly 1.7× smaller feature sizes compared to current EUV.

- Impact: Reduces the number of patterning steps, lowering cost and complexity while boosting yield.

Intel’s Deployment of High-NA EUV

- First Commercial Installation: Intel installed the world’s first High-NA EUV tool at its D1X fab in Hillsboro, Oregon in 2024 (source: Intel Newsroom).

- Production Ramp: By early 2025, Intel had two High-NA EUV machines in production, processing about 30,000 wafers per quarter (source: TrendForce).

- Machine Value: Each system costs around $380 million (source: TechPowerUp).

The 18A Node – Intel’s Breakthrough

- Timeline: Intel targets 18A production in 2025, with tape-outs already underway in 1H25.

- Technology Enhancements:

- RibbonFET (Intel’s GAA transistor): Improves performance-per-watt.

- PowerVia (backside power delivery): Reduces resistance and improves efficiency.

- High-NA EUV: Enables tighter scaling with fewer masks.

- Competitive Edge: Intel aims to leapfrog rivals like TSMC and Samsung by being the first to use High-NA EUV in production.

Challenges Ahead

- Yield Concerns: While early results are promising, achieving high yields at 18A remains a challenge (source: TrendForce).

- Cost & Complexity: Each High-NA tool is massive (165 tons) and extremely expensive, requiring significant fab modifications.

- Industry Competition: TSMC and Samsung are expected to adopt High-NA EUV later this decade, putting pressure on Intel to deliver first.

What This Means for the Industry

- For Intel: A chance to regain process leadership and strengthen its foundry business (IFS).

- For ASML: Validation of its High-NA EUV technology, with Intel as the flagship customer.

- For the Semiconductor Industry: A new era of scaling, enabling chips with trillions of transistors for AI, HPC, and advanced consumer devices.

Intel’s adoption of ASML’s High-NA EUV is more than a technical milestone—it’s a strategic bet on regaining semiconductor leadership. If Intel can overcome yield challenges and execute on 18A, it will set the stage for 14A and beyond, shaping the future of computing for the next decade.

Intel’s 18A Node: A New Era of Chip Manufacturing

Intel is making bold moves in the semiconductor arena, and their collaboration with ASML for the 18A process node is a game-changer. This partnership marks a significant step towards smaller, faster, and more efficient chips.

High-NA EUV: The Key to 18A

ASML’s High-Numerical Aperture (High-NA) Extreme Ultraviolet (EUV) lithography system is at the heart of Intel’s 18A breakthrough. This cutting-edge technology enables the creation of incredibly small features on silicon wafers, paving the way for denser and more powerful chips.

18A Node: More Than Just Shrinking Transistors

While shrinking transistors is a key aspect of 18A, it’s not the whole story. This node also brings several advancements:

| Feature | Benefits |

|---|---|

| RibbonFET Transistors | Improved performance and power efficiency compared to FinFET transistors. |

| PowerVia Technology | Enhanced power delivery and signal routing for faster and more reliable chips. |

| High-NA EUV Lithography | Enables smaller features and increased transistor density. |

Intel’s Ambitious Roadmap

Intel’s 18A node is part of their aggressive roadmap to regain leadership in chip manufacturing. They aim to deliver five new nodes in four years, culminating in the 18A node in the second half of 2024. This timeline puts them ahead of rivals like TSMC and Samsung.

Challenges and Outlook

While promising, the 18A node faces challenges, including high production costs and potential technical hurdles. However, Intel’s CEO, Pat Gelsinger, remains optimistic about the technology’s potential to surpass competitors and deliver significant performance improvements.

Implications for Consumers

The successful implementation of Intel’s 18A node could have far-reaching benefits for consumers. We can expect faster and more efficient processors in our laptops, desktops, and mobile devices. The advancements in chip technology could also drive innovation in areas like artificial intelligence, cloud computing, and even the automotive industry.

Key Takeaways

- The partnership between Intel and ASML to develop the TWINSCAN EXE5000 system using extreme ultraviolet (EUV) lithography represents a groundbreaking advancement in chip manufacturing, allowing for smaller, more powerful chips.

- Aimed at enhancing device performance across various gadgets without increasing their physical size or power consumption, this collaboration underscores a significant leap towards revolutionizing the tech industry.

- Intel’s ambitious future plans, including the introduction of HighNA EUV in their 18A process node and the development of GAA transistors, position them at the forefront of technological advancement, potentially outpacing competitors like TSMC.

- The strategic use of EUV lithography, a technique that relies on extremely precise light manipulation to etch microscopically small patterns on chips, showcases the innovation and sustained research efforts by both companies over the past decade.

- By prioritizing meticulous testing and cautious implementation over rushing into mass production, Intel ensures the reliability and efficiency of these state-of-the-art chip manufacturing processes, promising a significant impact on future electronics.

- As the industry anticipates Intel’s rollout of 18A node technology and advancements such as PowerVia and pattern shaping, these developments signal a transformative era in computing, with implications extending far beyond just improved gadget performance.

The Partnership between Intel and ASML

Intel and ASML have teamed up to bring forth a significant leap in chip technology. Together, they’re rolling out the TWINSCAN EXE5000 system. This system uses a super advanced technique called extreme ultraviolet lithography (EUV). It’s a big deal because it lets them make chips that are way smaller and way more powerful than before.

For a decade, these two tech giants have been working hand in hand. They’ve combined their brainpower to push the boundaries of what’s possible in chip manufacturing. This collaboration isn’t just about making things smaller and faster though. It’s about revolutionizing how devices around us work. Imagine gadgets that react in the blink of an eye or smartphones that can do more without needing a charge every few hours.

In December 2023, ASML handed over the first pieces of this groundbreaking system to Intel. It’s like they passed the baton in a relay race. Now, it’s Intel’s turn to take these tools and start experimenting. They’re not rushing into mass production right away. They want to test the waters, make sure everything’s just right. It’s a careful, deliberate approach that promises to change the game in electronics.

What’s truly fascinating is the scale and potential of this partnership. ASML forecasts sales of up to $4 billion in 2024 just from these high-tech tools. With Intel set to receive six out of the first ten tools, they’re poised to leap ahead of their competitors. It shows how much faith they have in this technology and each other. This isn’t a mere business deal; it’s a shared vision for the future of computing.

Intel’s ambitious plans don’t stop here. They’re already talking about their next big thing, the 18A node technology. It’s expected to hit the market even before others have caught up. Meanwhile, ASML’s expertise and innovative tools give Intel a significant advantage. This partnership is not just about staying ahead of the curve. It’s about setting new standards and opening doors to possibilities we’ve yet to imagine.

Unveiling the TWINSCAN EXE5000 System

Intel and ASML have teamed up to bring out the TWINSCAN EXE5000, a new machine that makes computer chips smaller and more powerful. This system is very important for technology, allowing gadgets like phones and computers to get better without getting bigger. It’s a big step for both companies and could change how devices are made.

The TWINSCAN EXE5000 uses something called extreme ultraviolet lithography, or EUV for short. This method lets the system create tiny parts on a chip, tinier than ever before. It’s like using a super fine pen instead of a regular one to draw more detailed pictures. This means chips can do more without needing more space.

Intel plans to start using this system soon. They got the first parts of it in December 2023. After some tests, they’ll make many chips with it. This is a big deal because making better chips quickly means new and improved gadgets for everyone.

The partnership between Intel and ASML is not just about making cool new things. It’s also big business. ASML expects to make up to $4 billion from selling these systems. Intel gets a big part of that, showing how much they’re investing in the future.

With the TWINSCAN EXE5000, Intel is looking ahead. They’re working on technology called the 18A node. This could make chips even smaller and faster. It’s clear they want to stay at the front of the tech race, always finding new ways to surprise us with what devices can do.

Understanding Extreme Ultraviolet (EUV) Lithography

Extreme Ultraviolet (EUV) Lithography is a way to make computer chips smaller and work faster. Think of it like a super-precise printer. Instead of ink, it uses light that’s almost like X-rays. This light can draw tinier lines on chips than ever before. The smaller the lines, the more stuff you can fit on a chip. That means your phone and computer can do more without getting bigger.

This technology is really advanced. It uses a special kind of light that’s hard to handle. Imagine trying to catch a shadow with your hands. That’s kind of what scientists have to do with this light. They use mirrors and lenses to direct it just right. It’s a big deal because it can make gadgets better without making them larger or eating up more power.

Intel and a company called ASML are working together on this. They’re using EUV to push the limits of what chips can do. Their newest machine, the TWINSCAN EXE5000, is like the future of chip making. It can create parts of a chip that are super tiny, way smaller than a human hair.

This isn’t just about making things smaller, though. It’s about making everything from phones to cars to appliances smarter and more efficient. As things get smaller, they also get cheaper to make in big numbers. This is good news for everyone who likes cool tech without a huge price tag.

So, EUV Lithography is kind of a big leap. It’s helping computers and all sorts of devices get better faster. And with companies like Intel and ASML leading the way, we’re heading into an exciting future of technology. Just imagine, in a few years, we could have gadgets that are way smarter and smaller than we’ve ever seen before.

The Decade-long Journey to Innovation

The road to today’s tech breakthroughs wasn’t quick. It took a solid ten years for experts at Intel and ASML to develop the extreme ultraviolet (EUV) lithography system. They aimed to make computer chips faster and smaller. This cutting-edge tech uses light, much like X-rays, to etch tiny patterns on chips.

In the early days, the idea seemed almost too bold. Chips were already getting smaller, but the industry needed them to shrink further without losing speed or power. Intel and ASML faced a huge challenge. How could they push the limits of what’s possible with chip manufacturing?

Step by step, they found answers. The introduction of the TWINSCAN EXE5000 system marked a turning point. This machine could produce chip parts tinier than ever before. It wasn’t just about making gadgets smaller. The real game-changer was enhancing device performance and cutting down costs.

Today, this tech is why smartphones, laptops, and other devices keep getting better. It’s a testament to the importance of investing in long-term research and development. Intel and ASML’s journey shows that big risks can lead to even bigger rewards.

Reports now suggest that this partnership could set new industry standards. With plans to extend EUV lithography down to 5 nanometers and hesitations about pushing it to 3 nanometers, they’re treading new ground. China’s fabs might find it hard to keep up, showcasing the strategic advantage of Intel and ASML’s collaboration.

In essence, this decade-long journey was more than just about creating the next big thing. It was about reshaping the future of technology, ensuring that gadgets not only become more efficient but also more accessible to people everywhere. This relentless pursuit of innovation has not only set Intel and ASML apart but also promises to drive the tech industry forward for years to come.

Intel’s Plans for the Future

Intel is on a quest to push the boundaries of chip technology. They’ve got big plans for their chips. In the next two to three years, Intel aims to use a new tech called HighNA EUV for their 18A process node. This is a big deal because it could make chips work better and use less power. But that’s not all. Intel’s also working on something called GAA transistors. They plan to bring this into play at the same time as HighNA EUV in the 18A tech. This could make Intel’s chips even smaller and faster.

But there’s a twist. While Intel is charging ahead, another big name in chips, TSMC, might not use this tech until much later, maybe around 2030. This difference in timing could give Intel a head start in developing even more advanced chips.

Intel’s not stopping with just one or two new ideas. They’re also introducing a clever way to power their chips called PowerVia. This starts with their 20A process. Then, they’ll make it even better in the 18A process. All these steps are part of a big plan to make chips that are not just smaller and faster but also don’t need as much power.

Another smart move by Intel is pattern shaping. This will start with the 20A process. Pattern shaping could make making chips simpler and skip a step called EUV double patterning. That means making chips could get a bit easier.

Intel’s got its eyes on the prize. Their 18A node is set to roll out really soon. They believe it’s a bit ahead of what TSMC is doing. TSMC won’t start their similar N2 chips until a few years after Intel. Plus, TSMC’s backside power technology won’t come out until after Intel’s. With all these plans, Intel’s shaping up to really change the game in chip technology.

Conclusion

Intel’s leap into HighNA EUV and GAA transistors marks a significant milestone in the semiconductor industry. Their forward-thinking approach, coupled with the introduction of PowerVia technology and pattern shaping, not only promises enhanced chip performance and reduced power consumption but also simplifies the manufacturing process. As Intel gears up for the rollout of their 18A node, they’re not just aiming to stay ahead in the game—they’re setting the stage to potentially redefine the future of chip technology. This bold move could indeed place them at the forefront, challenging competitors and shaping the next generation of power-efficient chips.

Frequently Asked Questions

What advancements are Intel making in chip technology?

Intel is implementing HighNA EUV and GAA transistors in their 18A process node to enhance chip performance and reduce power consumption. This move aims to give Intel a competitive advantage in the industry.

How could Intel’s new technologies affect its competition with TSMC?

By introducing HighNA EUV and GAA transistors earlier than TSMC, Intel could gain a competitive edge, potentially leading in the development of more advanced and power-efficient chips.

What is PowerVia technology, and how does it benefit chip manufacturing?

PowerVia is Intel’s upcoming technology primarily focused on improving chip efficiency. It simplifies the manufacturing process by optimizing the way power is delivered to the chip, reducing overall power consumption.

What does pattern shaping mean in the context of chip production?

Pattern shaping refers to a technique used in chip manufacturing to enhance the precision and efficiency of semiconductor patterning. This innovation is part of Intel’s efforts to streamline manufacturing processes and improve chip performance.

When is Intel’s 18A node expected to roll out?

Intel plans to roll out their 18A node in the near future, though the specific timeline has not been disclosed. This rollout is part of Intel’s strategy to lead in the development of advanced and power-efficient chip technologies.